STRAPPING MACHINES:

Semi-automatic strapping –

Semi-automatic strapping machines are used to apply plastic straps to packages or bundles in a variety of industries, including manufacturing, warehousing, distribution, and shipping. These machines typically have a manual feed system, in which the operator places the package in the machine and initiates the strapping process. The machine then automatically tensions, seals, and cuts the strap

Automatic strapping machines –

Automatic box strapping machine is a dynamic machine that provides a boost to your packaging line. These machines can be either hooked to an assembly line or can be operated individually. Global Packaging offers fully automatic strapping machines that are used with polypropylene straps. They are most widely use in food and beverage, e-commerce industries to automate packaging lines.

Online strapping systems –

Online strapping systems are automated packaging lines that use strapping machines to secure packages as they move through the line. These systems are often used in combination with other packaging equipment, such as conveyors and labeling machines, to create a unmanned and efficient packaging process.

Pallet Strapping Machine –

A pallet strapping machine or automatic pallet strapper is used to join and bind pallets together by means of PP or PET straps. Poly Ethylene Terephthalate (PET) Strap is used in an Automatic Pallet Strapping Machine to fasten the pallets firmly from each direction and prepare the product for further shipment. Usually, pallet strapping machines are used to bind pallets together for transportation. The strapping helps keep the pallet in place and allows the goods to be transported easily and without wear and tear.

CARTON SEALING MACHINES:

Standard carton sealing machines –

Standard carton sealing machines, also known as case sealers, are used in a variety of industries to close and seal boxes or cartons. These machines are designed to be efficient and easy to use, and they can be used to seal boxes of various sizes and shapes. With BOPP tapes, Kraft Paper & Gluing.

Random carton sealing machines –

Random carton sealing machines are similar to standard carton sealing machines, but they are designed to handle a wider range of box sizes and shapes. These machines use sensors to auto adjust different box sizes to facilitate, smooth sealing process.

Top flap folding machines –

Top flap folding machines are used to fold the flaps on top of a box or carton in preparation for sealing. These machines are typically used in conjunction with a standard or random carton sealing machine to eliminate manned process of folding the flaps. This machine can be integrated with automated conveyors.

Edge sealing machines –

Edge sealing machines are used to seal the edges of a box or carton, typically along the seams where the flaps meet. These machines are often used in conjunction with a standard or random carton sealing machine to provide an extra layer of protection and security for the contents of the box.

STRETCH WRAPPING MACHINES:

Pallet stretch wrapping machines –

Pallet stretch wrapping machines are used to wrap stretch film around a pallet of goods to secure and stabilize the load during transportation. The stretch film helps to hold the items in place, protecting them from damage and spills.

Box stretch wrapping machines –

Box stretch wrapping machines are similar to pallet stretch wrapping machines, but they are designed to wrap stretch film around boxes or other small packages. These machines are often used in warehouses and distribution centers to secure and protect smaller items during shipping.

Orbital wrapping machines –

Orbital wrapping machines are used to wrap stretch film around large, irregularly shaped loads that cannot be wrapped on a traditional pallet stretch wrapping machine. These machines use a rotating arm to apply the film evenly around the load, ensuring that it is securely wrapped and protected.

CASE ERECTOR:

Standard Case Erector –

A standard case erector is a type of packaging equipment that is used to automatically form and set up cardboard boxes or cases from flat sheets of corrugated cardboard. These machines are commonly used in the packaging and distribution industry to efficiently and accurately assemble boxes for shipping and storage.

There are several potential uses for a standard case erector in a variety of industries:

Manufacturing: Standard case erectors can be used in manufacturing facilities to package finished products for distribution to retailers or customers.

E-commerce: Online retailers can use case erectors to efficiently package orders for shipment to customers.

Food and beverage: Standard case erectors can be used to package food and beverage products for distribution to supermarkets and other retail outlets.

Pharmaceuticals: Case erectors can be used to package pharmaceutical products for distribution to hospitals and pharmacies.

Industrial: Standard case erectors can be used to package industrial products such as machinery and equipment for shipping and storage.

STRAPPING TOOLS:

Battery power tools, pneumatic strapping tools, and manual strapping tools are used for a variety of applications in various industries. These tools are used to apply straps, typically made of plastic or steel, around packages or bundles of items in order to secure them for transportation or storage.

Battery power tools –

Battery power tools are powered by a rechargeable battery and are typically cordless, making them convenient and portable. They are used in a variety of applications, including construction, automotive repair, and packaging.

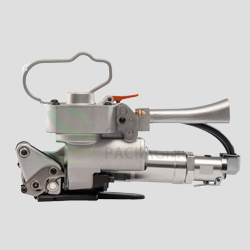

Pneumatic strapping tools –

Pneumatic strapping tools are powered by compressed air and are commonly used in heavy-duty applications, such as securing large or heavy packages. They are faster and more powerful than manual tools and are often used in industrial settings.

Pneumatic steel strapping tools –

Pneumatic steel strapping tools are used to apply steel straps, which are stronger and more durable than plastic straps. They are typically used in heavy-duty applications where a high level of stability and security is required.

Manual strapping tools –

Manual strapping tools are operated by hand and are suitable for a wide range of applications, including packaging, bundling, and securing items for transportation. They are typically less expensive, portable and used for factories that have less packaging load.

CONSUMABLES:

PP strap, or polypropylene strap, is a type of strap made from a Polymer called polypropylene. It is commonly used in a variety of applications, including:

PP strap –

It is made from 100% pure Polypropylene granules which makes it the ideal choice for palletizing, packaging, and bundling. Polypropylene (pp) strapping rolls are preferred for strapping on fully automated packaging lines. They are a good substitute for steel straps and come in different sizes and thicknesses.

PET strap –

PET strap, or polyethylene terephthalate strap, is another type of plastic strap that is commonly used in packaging and shipping applications.Due to its high density and properties it is majorly used for applications where weight of the product or safety required is high .example-Pallet packaging, ingot packaging, steel coils.

Bopp tape –

Bopp adhesive tape is made of thermoplastic polymers, they can be used at any temperature. The strength of the tape is very high which is why it is used for packaging. Bopp tape full form is Biaxially Oriented Polypropylene.

Stretch film –

Stretch film, also known as stretch wrap, is a type of plastic film that is used to wrap and secure items for storage or transportation. It is commonly used in the shipping and packaging industry to hold together boxes, and pallets, and also protect goods from environmental damages