Selecting the best heavy-duty semi-automatic strapping machine for your packaging needs is crucial for ensuring efficiency, durability, and cost-effectiveness in your operations. Whether you’re managing a warehouse, shipping facility, or industrial production line, choosing the right strapping machine can significantly streamline your packaging process. With a wide variety of machines available on the market, understanding the key features, such as tension control, ease of use, speed, and compatibility with different strap materials, is essential. In this blog, we will explore the factors you need to consider to make an informed decision and find the perfect heavy-duty semi-automatic strapping machine for your business.

What is a Heavy-Duty Semi-Automatic Strapping Machine?

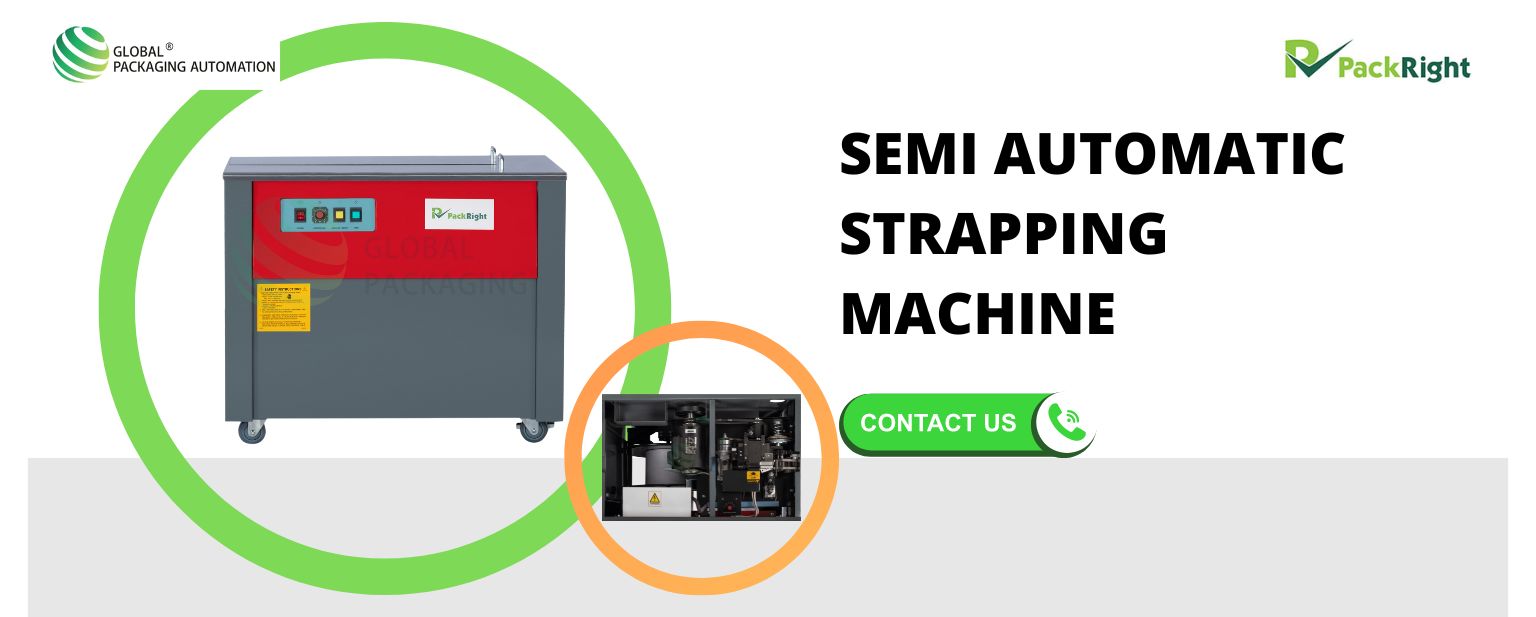

A heavy-duty semi-automatic strapping machine is a powerful tool designed to simplify the process of securing packages, boxes, or large items with strapping material, typically plastic or metal straps. Unlike fully automatic machines, which handle the entire process from strap feeding to cutting, a semi-automatic machine requires some manual intervention, such as feeding the strap around the package by hand. However, the machine takes care of tightening the strap and sealing it, providing a strong and secure bond. These machines are specifically built for industrial use, where packaging large, heavy, or high-volume items is a routine task. They offer the reliability and strength needed for demanding packaging applications without the complexity and higher costs associated with fully automatic systems.

Key Features Of Semi Automatic Box Strapping Machine

- Durability: Heavy-duty semi-automatic machines are designed to withstand harsh industrial environments. They are typically built with robust materials like stainless steel or heavy-gauge metal, ensuring they can handle continuous use without frequent breakdowns.

- Speed: These machines can significantly speed up the packaging process compared to manual strapping. While they require some manual input, the time saved in tensioning and sealing the strap is substantial, especially when packaging large volumes.

- Strap Compatibility: Heavy-duty machines are compatible with a variety of strapping materials, such as polypropylene (PP) or polyester (PET) straps. The machine can adjust to different strap widths and thicknesses, allowing for flexibility depending on the packaging needs.

- Tension Control: One of the key components is adjustable tension control. This feature allows you to set the desired strap tension based on the type of package. For heavy loads, you’ll need higher tension, whereas lighter packages require less force to avoid damage.

- Seal Mechanism: These machines use either heat or friction to seal the strap ends together, ensuring a secure bond. This automatic sealing process ensures consistency and saves time.

- Mobility and Size: Most heavy-duty semi-automatic machines are compact and may come with casters or wheels, making them easy to move around the warehouse or packaging area.

Advantages

Compared to Manual Machines:

- Time and Effort Savings: Manual strapping requires the user to tighten and seal the strap by hand, which is labor-intensive and time-consuming, especially for large quantities. Semi-automatic machines automate the tensioning and sealing, significantly reducing physical effort and boosting productivity.

- Consistency: A semi-automatic machine ensures a consistent level of tension on each package, which is hard to achieve manually. This results in uniformly strapped packages, reducing the risk of items shifting or becoming loose during transportation.

- Improved Safety: Manually tightening straps can be physically straining and even dangerous for workers, especially when dealing with heavy loads. Semi-automatic machines reduce the risk of injury by automating the tensioning process.

- Eliminate a use of metal clips: metal clips can provide several benefits, including cost savings, weight reduction, improved safety, corrosion resistance, and sustainability, making it an attractive option for many industries.

Compared to Semi Automatic Strapping Machine

A Semi-Automatic Strapping Machine is commonly used in packaging to secure products with straps. Here’s an elaboration of its characteristics and benefits:

Operation:

- The operator manually feeds the strap around the product, and the machine automatically tightens, seals, and cuts the strap.

- It’s ideal for low to medium-volume operations where full automation isn’t required.

Ease of Use:

- User-friendly and easy to operate, even for unskilled workers.

- Requires manual engagement to start the strapping process but performs the sealing automatically.

Cost-Effective:

- More affordable than fully automatic machines, making it a popular choice for small to medium-sized businesses.

- Minimal maintenance and repair costs.

Applications:

- Suitable for various industries such as food, pharmaceuticals, logistics, and more.

- Often used to bundle boxes, newspapers, parcels, or lightweight packages.

Efficiency:

- Speeds up the packaging process compared to fully manual strapping.

- While not as fast as a fully automatic machine, it offers a good balance between speed and cost.

Flexibility:

- Works with different strap materials like polypropylene and polyester.

- Can be adjusted for different package sizes and shapes.

Factors to Consider When Selecting the Best Strapping Machine

- Packaging Volume and Frequency: One of the first things to consider when selecting a heavy-duty semi automatic strapping machines is your packaging volume and how frequently you’ll be using the machine. If you run a high-volume operation that requires strapping hundreds of packages per day, you’ll need a machine with the capacity to handle this workload efficiently. Machines designed for lower-volume operations may overheat or wear out quickly if used beyond their intended capacity. It’s essential to choose a machine that aligns with your production needs, ensuring it can operate continuously without frequent downtimes. On the other hand, if your packaging needs are moderate, a smaller, less robust machine might suffice, saving you costs without compromising performance.

- Type of Packages: The size, weight, and type of packages you’re strapping play a significant role in determining the right strapping machine. Large or heavy packages, such as industrial goods, machinery, or pallets, will require a machine with higher tension capabilities and the ability to accommodate thicker, stronger straps. Meanwhile, lighter packages, such as boxes or retail items, can use machines designed for lower tension and thinner straps. Additionally, consider the shape and rigidity of the packages. Irregularly shaped or fragile items might need more customized tension settings to avoid damage, which makes adjustable tension control a key feature (discussed below).

- Strap Type Compatibility: Not all strapping machines are compatible with every type of strap. The two most common strapping materials are polypropylene (PP) and polyester (PET). Polypropylene straps are more cost-effective and suitable for lighter loads, while polyester straps are stronger and ideal for heavy-duty packaging. Some machines may only work with specific strap widths and materials, so it’s crucial to verify that the machine you choose supports the strap type you plan to use. Having a machine that can switch between different strap materials or adjust to various thicknesses and widths offers greater flexibility, especially if your packaging needs vary over time.

- Adjustable Tension Control: The ability to adjust the tension applied to the strap is a critical factor when selecting a strapping machine. Different packages require different levels of tension to ensure secure strapping without damaging the product. For example, heavy packages may require high tension to hold them securely, while more delicate or lightweight items may need lower tension to avoid crushing or deformation. A machine with adjustable tension settings allows you to fine-tune the strapping process for each type of package, ensuring safety and effectiveness across a variety of products.

- Ease of Use and Maintenance: The efficiency of your packaging process is closely linked to how easy your strapping machine is to operate and maintain. Look for machines that are user-friendly, with intuitive controls and straightforward operation. This is especially important if multiple employees will be using the machine or if training time is limited. Additionally, consider the machine’s maintenance requirements. Machines with simple designs and easy access to parts are typically easier to maintain, reducing downtime for repairs. It’s also beneficial to choose a machine from a manufacturer that provides good customer support and readily available spare parts.

- Machine Durability and Build Quality: Since heavy-duty strapping machines are often used in industrial settings, they need to be durable and well-built to withstand constant use and tough conditions. Machines made from high-quality materials, such as steel or heavy-duty plastics, are more likely to offer long-term reliability. Additionally, check whether the machine’s components, such as the tensioning mechanism, sealing system, and motors, are built to last. Investing in a durable machine may have a higher upfront cost, but it will reduce the need for repairs and replacements over time, ultimately saving you money.

Evaluating Your Budget

Balancing Cost with Quality and Functionality

When investing in a heavy-duty semi-automatic strapping machine, it’s essential to strike the right balance between cost, quality, and functionality. While it may be tempting to opt for the cheapest available machine, it’s important to consider the long-term implications. A lower-priced machine might lack essential features like adjustable tension control or durability, which could lead to inefficiencies, increased maintenance, or frequent repairs. On the other hand, the most expensive option might come with advanced features that your packaging needs don’t require, making it an unnecessary expenditure.

The key is to assess the machine’s core functionalities and ensure that it meets your packaging requirements without overspending on unnecessary extras. Prioritize machines that offer a good blend of features like ease of use, reliable tension control, and compatibility with your strap materials. Compare models within your budget range to find the one that provides the best value for money while ensuring high performance and quality.

Long-Term Cost Savings through Durability and Performance

One of the most significant considerations when evaluating your budget is the machine’s durability and overall performance. While a higher-quality, more durable machine may come with a larger initial price tag, it can save you significant amounts of money in the long run. Durable machines made from high-quality materials are less likely to break down, reducing repair costs and minimizing production downtime. Moreover, a well-built machine will last longer, allowing you to maximize your return on investment.

Additionally, a machine that operates efficiently and requires less maintenance will reduce operational costs over time. For example, reliable tension control prevents damage to products, and consistent performance ensures that packaging processes remain smooth and efficient. By choosing a machine with strong build quality and dependable features, you’re making a smart long-term investment that can lead to cost savings in maintenance, repairs, and replacement over the years.

Supplier Reputation and After-Sales Support

Importance of Choosing Reputable Suppliers

When purchasing a heavy-duty semi-automatic strapping machine, the reputation of the supplier is as important as the machine itself. A reputable supplier ensures that you are getting a high-quality, reliable machine that will meet your packaging needs. Established suppliers are known for providing machines that are built to last and offer consistent performance. They also have a track record of customer satisfaction, which is a strong indicator that you can trust the product and the company.

By choosing a well-known and trusted supplier, you reduce the risk of receiving faulty or substandard equipment. Reputable suppliers are more likely to offer transparent product information, and warranties, and provide technical support to ensure the machine functions properly in your facility. Additionally, suppliers with a solid reputation are more likely to have been in the industry for a long time, meaning they have the experience and expertise to recommend the right machine for your specific needs.

Availability of Spare Parts and After-Sales Services

After purchasing the machine, ongoing support is crucial for its long-term performance. Machines, especially those used in heavy-duty operations, require maintenance and occasional part replacements. It’s essential to ensure that the supplier you choose offers comprehensive after-sales support, including the availability of spare parts. Without easy access to replacement parts, even minor issues with the machine could lead to costly delays in your packaging process or force you to replace the machine sooner than expected.

Suppliers who offer robust after-sales services, such as maintenance assistance, technical support, and warranty services, help ensure the machine continues to perform optimally. Good after-sales service also means that if something goes wrong with the machine, you have immediate access to expert help, reducing downtime and keeping your operation running smoothly. A reliable supplier should offer training for your staff on how to operate and maintain the machine, as well as a support system to address any operational challenges.

Choosing a supplier with a strong after-sales service commitment ensures that your investment is protected, and any issues that arise are resolved quickly and efficiently.

Conclusion

Selecting the best heavy-duty semi-automatic strapping machine for your packaging needs is a critical decision that requires careful consideration of several factors. From understanding your packaging volume and the types of packages you handle to evaluating the machine’s durability, tension control, and ease of maintenance, every aspect plays a role in ensuring you make a smart investment. Balancing cost with quality is key, as a well-built, durable machine will offer long-term cost savings and reliable performance. Additionally, partnering with a reputable supplier who provides strong after-sales support, including access to spare parts and technical assistance, will ensure your machine operates efficiently for years to come. By making an informed choice, you can enhance your packaging process, improve productivity, and protect your products during transit, ultimately boosting your business’s efficiency and bottom line.

Global Packaging Automation stands out as the premier supplier of Semi-Automatic Box Strapping Machines in Mumbai, catering to a diverse range of businesses. Here are several compelling reasons to choose us as your trusted supplier:

- High-Quality Machines: Our strapping machines are built to last, providing efficient and reliable performance across all industries and products.

- Comprehensive After-Sales Support: We offer exceptional after-sales service, including installation, training, and ongoing maintenance support to ensure your machines operate at their best.

- Custom Solutions: Our extensive range of strapping machines can be fully customized to meet your unique packaging requirements, ensuring you get the right solution for your business.

- Affordability: We are committed to providing high-quality equipment at competitive prices, making us the ideal choice for businesses looking for value.

If you’re interested in purchasing a strapping machine in Navi Mumbai or have any inquiries, please don’t hesitate to contact us at +91 7738819711 or email us at marketing@globalpackindia.com. Watch our latest video on our channel, Global Packaging Automation LLP.

Explore our wide range of products and find the perfect solution for your packaging needs by clicking here for more information. With Global Packaging Automation, you can trust that you’re making a smart investment in your business’s efficiency and productivity.