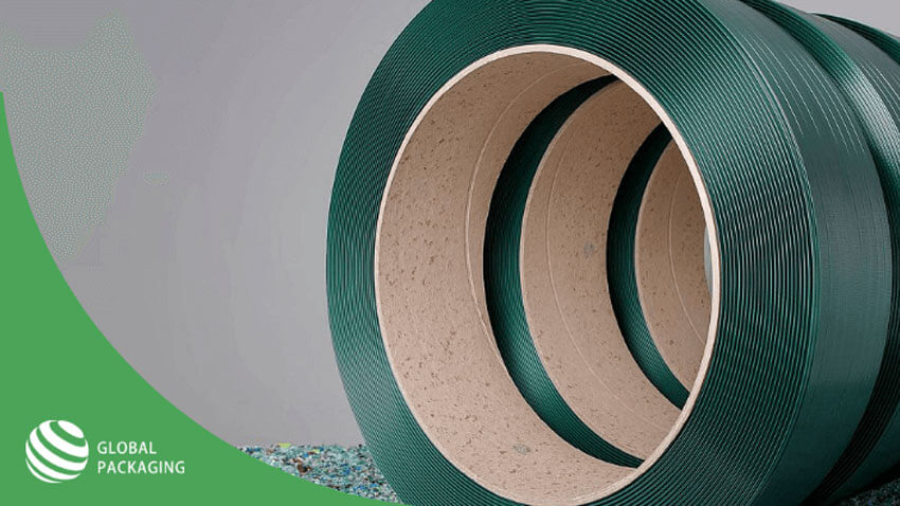

With sustainability being the new focus for the packaging industry, there have been many innovations when it comes to the production use of existing equipment, with one of the latest additions being the recyclable PET strap roll. Made of polyethylene terephthalate, the use of recyclable PET strap has resulted in more sustainable strapping, which is a widely-used operation for packaging and shipping.

The basic principle of preparing a recyclable PET strap roll is to use waste plastic bottles for the production of straps. The bottles are collected and broken down into smaller flakes called regrind. These are dried first, before getting converted into flakes. The resulting product is then melted, which results in the formation of pallets. The PET straps are made using these pallets. Once this strap is used for a specific purpose, it can be recycled to make another product.

There are many advantages of replacing regular straps with PET straps, with the foremost one being the option of recycling, which saves the environment from the detrimental effects of plastic. Another advantage is reduced soil pollution, which is a consequence of the continuous use of non- recyclable plastic. Also, this production process results in lower carbon emissions as compared to the other processes that are used for making plastic straps. This is yet another factor that helps in reducing the environmental costs involved in industrial processes.

Considering the many benefits of recyclable PET straps roll, it is only wise to include them in the packaging line. The recyclability of this material does not compromise the functionality of this strap in any way, thus making it a viable strapping option.