High Speed Strapping Machine Efficient packaging is the backbone of the corrugated box industry, where precision, speed, and reliability are essential to meet the growing demand for quality products. Corrugated boxes serve as the cornerstone of modern logistics and storage, requiring secure and consistent strapping to ensure their structural integrity during transit. A well-packaged product not only guarantees safe delivery but also reflects the professionalism of the manufacturer, making efficient packaging solutions a top priority.

In this dynamic industry, the choice of equipment plays a crucial role in streamlining operations and maintaining high standards. The PR 305P Automatic Strapping Machine emerges as a standout solution, tailored specifically for the unique challenges faced by corrugated box manufacturers. Its state-of-the-art design, superior performance, and user-friendly features make it an ideal choice for businesses looking to enhance efficiency and reduce downtime. Whether it’s for high-volume production or improving overall packaging quality, the PR 305P High Speed Strapping Machine sets a new benchmark in the industry.

Overview Of PR 305P High Speed Strapping Machine

The PR 305P High Speed Strapping Machine is engineered to address the dynamic needs of the packaging industry, particularly for corrugated box manufacturers. Its innovative features make it a standout solution in modern packaging processes. The PR 305P is a fully automatic box strapping machine featuring an advanced PCB control panel, engineered for effortless operation and low maintenance costs. Its single cam operation ensures simplicity and cost-effectiveness, making it an efficient choice for manufacturers.

Built with extra-hardened internal and external components, the PR 305P is engineered for durability and extended operational life. It serves as an excellent stand-alone strapping solution while also integrating effortlessly into automated packaging lines, significantly enhancing overall productivity.

One of its standout features is the top press mechanism, which compresses products during strapping—a critical requirement for industries like corrugation, textiles, and printing. This functionality ensures secure and reliable packaging, meeting the high standards of demanding industries.

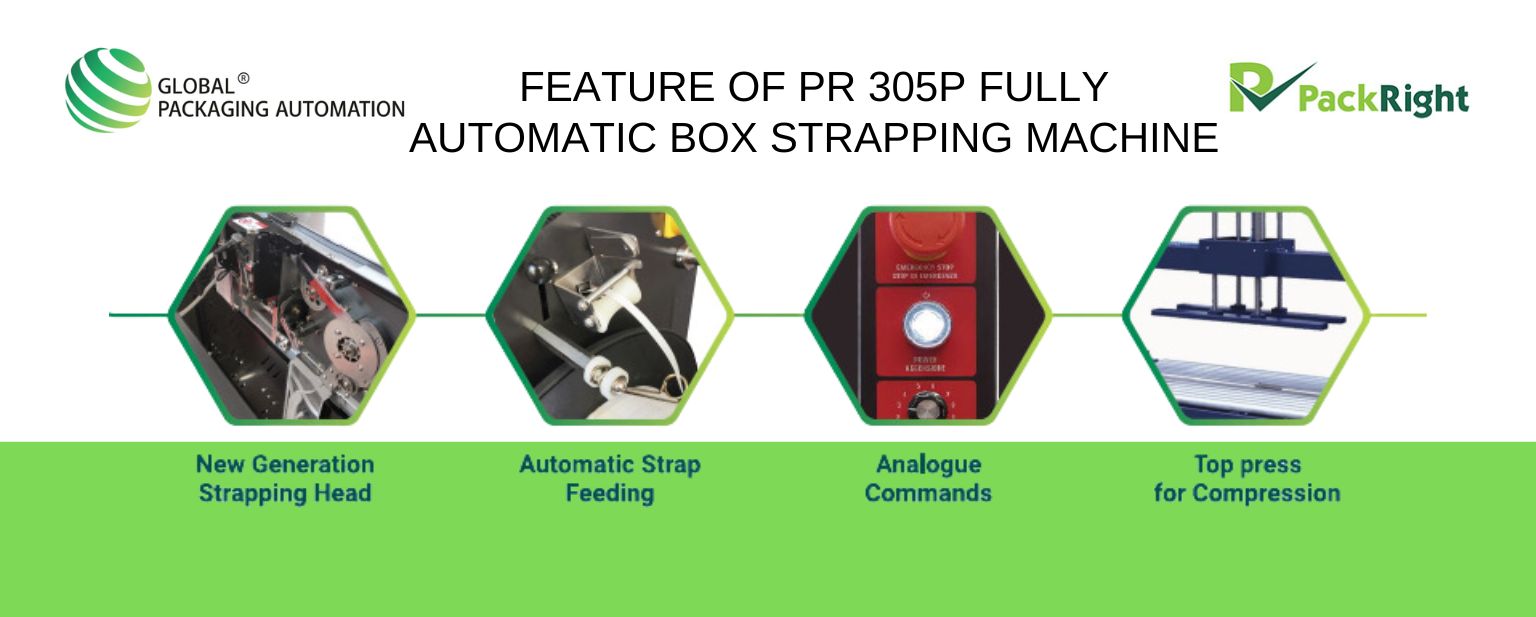

Features of the PR 305P Fully Automatic Strapping Machine

- Advanced Technology: Cutting-Edge Components: The PR 305P strapping machine is built with state-of-the-art technology that sets it apart from conventional machines. Equipped with precision engineering and modern automation features, it ensures consistent and secure strapping every time. Its advanced sensors detect box dimensions and adjust strapping tension automatically, reducing the risk of over-tightening or loose straps. The integration of intelligent control systems allows for seamless operation and adaptability, making it a dependable choice for the fast-evolving corrugated box industry.

- High-Speed Performance: Meeting Large-Scale Demands: Speed is a critical factor in high-volume production environments, and the PR 305P delivers exceptional performance to meet these demands. Capable of strapping hundreds of boxes per hour, it significantly reduces bottlenecks in the packaging line. Its rapid cycle time ensures that manufacturers can keep up with large-scale operations without sacrificing quality. This high-speed performance not only boosts productivity but also shortens delivery timelines, allowing manufacturers to stay ahead of competitors.

- User-Friendly Design: Ease of Operation and Maintenance: The PR 305P is designed with user convenience in mind, making it easy for operators to handle even with minimal training. Its intuitive interface simplifies operation, allowing staff to adjust settings quickly and efficiently. Maintenance is equally straightforward, thanks to the machine’s modular design and readily accessible components. This reduces downtime and ensures that manufacturers can focus on production rather than repairs. The user-friendly design also minimizes the learning curve for new operators, enhancing workplace efficiency.

- Energy Efficiency: Reducing Operational Costs: In today’s environmentally conscious market, energy efficiency is a vital consideration for manufacturers. The PR 305P excels in this area, consuming significantly less power than traditional strapping machines. Its energy-efficient design not only lowers electricity bills but also contributes to sustainability goals. With features like automatic shutoff during idle periods, the machine optimizes energy usage without compromising performance, making it a cost-effective and eco-friendly choice for corrugated box manufacturers.

Benefits of the PR 305P for Corrugated Box Manufacturers

The PR 305P High Speed Strapping Machine is a powerful tool designed to address the specific challenges faced by corrugated box manufacturers. Its innovative features translate into tangible benefits, ensuring efficiency, cost savings, and high-quality packaging. Below are detailed explanations of its advantages:

a. Increased Productivity

The PR 305P’s high-speed mechanism is a game-changer for manufacturers who deal with high production volumes. Its ability to strap boxes at rapid cycles ensures that production timelines are met without compromising quality.

- Time-Saving: The machine’s speed allows operators to strap significantly more boxes per minute compared to manual or semi-automatic alternatives, freeing up resources and increasing output.

- Bulk Order Handling: For large-scale orders, the PR 305P’s consistent performance minimizes bottlenecks and keeps production lines moving efficiently, even during peak demand.

b. Cost Efficiency

The PR 305P is designed to reduce operational costs while maximizing output, making it an economical choice for businesses.

- Reduced Manual Labor: By automating the strapping process, the machine minimizes the need for manual intervention, cutting labor costs and reducing the risk of human error.

- Energy-Efficient Design: With its optimized energy consumption, the PR 305P not only lowers electricity bills but also supports sustainable manufacturing practices.

c. Enhanced Strapping Quality

Strapping consistency is critical for corrugated boxes to ensure secure packaging during storage and transit. The PR 305P excels in this area.

- Precision Tensioning: The machine applies uniform tension to every strap, ensuring that the boxes are securely fastened without over-tightening or damaging the packaging.

- Damage Prevention: High-quality strapping prevents boxes from shifting or opening during transportation, reducing the likelihood of product damage and customer complaints.

d. Versatility and Adaptability

The PR 305P is built to cater to the diverse needs of corrugated box manufacturers by offering unparalleled flexibility.

- Multi-Size Compatibility: The machine easily adjusts to strap boxes of various sizes and materials, eliminating the need for multiple machines on the production floor.

- Seamless Integration: Its compact design and advanced features allow it to integrate smoothly into existing production lines, whether as a stand-alone unit or part of a fully automated system.

e. User-Friendly Features

Ease of operation and minimal maintenance are key factors that set the PR 305P apart from other machines in its class.

- Intuitive Controls: The machine’s control panel is simple to use, allowing operators to quickly learn its functions and reduce setup times.

- Safe Operation: Designed with worker safety in mind, the PR 305P includes safety features to minimize risks during use.

- Minimal Maintenance: The durable components and streamlined design ensure that maintenance is infrequent and straightforward, reducing downtime.

Conclusion

In conclusion, the PR 305P High Speed Strapping Machine stands out as a game-changer for corrugated box manufacturers. Its unparalleled speed, precision, and durability ensure seamless operations, reducing downtime and enhancing productivity. The machine’s user-friendly design and compatibility with high-demand environments make it a reliable investment for businesses striving for excellence in packaging. By choosing the PR 305P, manufacturers not only optimize their processes but also position themselves to meet growing market demands with efficiency and confidence. Invest in the PR 305P and elevate your packaging operations to new heights!

Global Packaging Automation is your premier choice for PR 305P High Speed Strapping Machine in India, offering high-quality, durable, and efficient solutions for businesses of all sizes and industries. We provide exceptional after-sales service, including installation, training, and maintenance, and our machines can be fully customized to meet your specific packaging needs. With a commitment to delivering reliable and affordable equipment, we ensure optimal results for all your packaging requirements. For inquiries or to purchase, contact us at +917738819711 or email info@globalpackindia.com. Watch our latest video on our channel, Global Packaging Automation LLP. Explore our wide range of fully automatic box strapping machine products by clicking here for more information.